Natamycin , ≥95%(HPLC) , 7681-93-8

Synonym(s):

Natamycin;Natamycin preparation;Natamycin, Pimafucin;Pimaricin;Pimaricin, Streptomyces chattanoogensis - CAS 7681-93-8 - Calbiochem

CAS NO.:7681-93-8

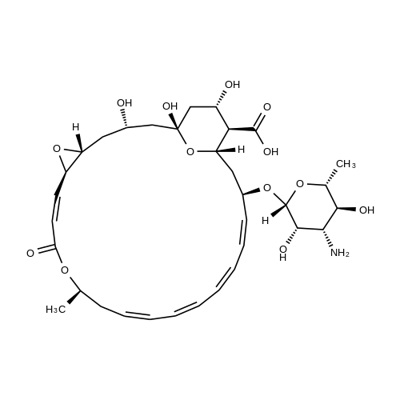

Empirical Formula: C33H47NO13

Molecular Weight: 665.73

MDL number: MFCD00135085

EINECS: 231-683-5

| Pack Size | Price | Stock | Quantity |

| 1G | RMB49.60 | In Stock |

|

| 5G | RMB96.80 | In Stock |

|

| 25G | RMB324.80 | In Stock |

|

| 100G | RMB1128.80 | In Stock |

|

| others | Enquire |

PRODUCT Properties

| Melting point: | 2000C (dec) |

| alpha | D20 +278° (c = 1 in CH3COOH) |

| Boiling point: | 952℃ |

| Density | 1.0 g/mL at 20 °C(lit.) |

| bulk density | 200kg/m3 |

| refractive index | 1.5960 (estimate) |

| Flash point: | >110°(230°F) |

| storage temp. | Keep in dark place,Inert atmosphere,2-8°C |

| solubility | Soluble in DMSO |

| pka | pKa 4.6(50% aq. MeOEtOH) (Uncertain);8.35 (Uncertain) |

| form | aqueous suspension |

| color | Cream colored |

| Water Solubility | 0.41g/L(21 ºC) |

| Sensitive | Light Sensitive |

| Merck | 13,6453 |

| BRN | 1614878 |

| Stability: | Light sensitive |

| InChIKey | NCXMLFZGDNKEPB-FFPOYIOWSA-N |

| LogP | 0.880 (est) |

| EPA Substance Registry System | 6,11,28-Trioxatricyclo[22.3.1.05,7]octacosa-8,14,16,18,20-pentaene-25-carboxylic acid, 22-[(3-amino-3,6-dideoxy-.beta.-D-mannopyranosyl)oxy]-1,3,26-trihydroxy-12-methyl-10-oxo-, (1R,3S,5R,7R,8E,12R,14E,16E,18E,20E,22R,24S,25R,26S)- (7681-93-8) |

Description and Uses

Natamycin was discovered in the 1950s. As described by Struyk et al. A new crystalline antibiotic, pimaricin, has been isolated from fermentation broth of

a culture of a Streptomyces species, isolated from a soil sample obtained near

Pietermaritzburg, State of Natal, Union of South Africa. This organism has been

named Strepyomyces natalensis. The original name "pimaracin" can be found in

earlier publications but it is no longer accepted by the WHO. Natamycin is

classified as a macrolide polyene antifungal and is characterized by a macrocyclic

lactone-ring with a number of conjugated carbon–carbon double bonds.

The full chemical name is 22-(3-amino-3,6-dideoxy-b-D-manno pyranosol) oxy-

1,3,26 trihydroxy-12-methyl-10-oxo-6,11,28-trioxiatri [22.3.1.05.7] o catosa-

8,14,16,18,20-pentanene-25-carboxylic acid.

Natamycin has a low solubility in water (approximately 40 ppm), but the

activity of neutral aqueous suspensions is very stable. Natamycin is stable to heat

and it is reported that heating processes for several hours at 100 C lead to only

slight activity losses. Natamycin is active against almost all foodborne yeasts and

molds but has no effect on bacteria or viruses. The sensitivity to natamycin in vitro

(minimal inhibitory concentration) is in most cases below 20 ppm.

Natamycin acts by binding irreversibly with ergosterol and other sterols, which

are present in the cell membranes of yeasts and vegetative mycelium of molds. It disrupts the cell membrane and increases the cell permeability, which finally leads

to cell death. The fungicidal of natamycin is an ‘‘all-or-none’’ effect, which

destroys the cell membrane of the target cells.

Due its interaction with ergosterol, which is a major constituent of fungal cells,

it is unlikely that fungi will develop resistance. So far, after many decades of use,

no development of resistance has been reported. Natamycin is mostly used for

surface applications, particularly for treating surfaces of hard cheese and salamitype

sausages. One of the advantages over sorbate is that even the dissolved

fraction of natamycin hardly migrates into the food matrix. Natamycin can be applied by spraying the surface (e.g. of cheese), by dipping, by

applying natamycin via coating emulsions or by direct addition.

The antifungal efficacy of natamycin has been extensively studied and a substantial

amount of scientific papers have been published. Comprehensive overview

articles are available. However, due to its long history of use, no data

on application studies have been published recently.

Pimaricin is a preservative for use as a coating on the surface of italian cheeses to prevent the growth of mold or yeast. It is tasteless, odorless, colorless, and does not penetrate the cheese. It is very active against virtually all molds and yeasts, but does not affect bacteria, thus not affecting the ripening and flavor improvement process of cheese. It can be applied as a dip, spray, or by other methods such as incorporation into the cheese coatings. It is used at levels ranging from 300 to 2,000 ppm.